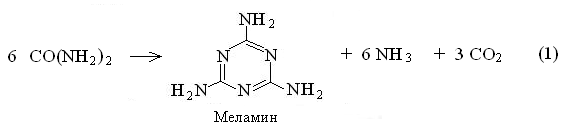

2. Today most industrial manufacturers use urea in the following reaction:

This method of melamine production has been the main method used in the industry since the late 1960s and up to the present time. Until the 70s of the last century both types of melamine production plants were in operation: from dicyandiamide and from urea.

NIIK has developed its own method for continuous production of melamine from dicyandiamide. Based on the above technology HP unit with capacity 6000 t/y was designed in chemical factory in Kirovakan (Republic of Armenia).

With the start-up in 1968 in Kirovakan of a plant for melamine production from urea on the basis of the equipment purchased from Montedison, JSC NIIK focused on the process of mastering the acquired equipment, solving the problems of improving the reactor heating system, its intensification, melamine quality, waste water treatment.

Further works allowed to design and launch in 1985 in Kirovakan a new plant for melamine production from urea with the capacity of 10 000 tpy, which surpassed the similar one (made by Montedison) by a number of parameters (improved reactor unit, product quality, wastewater treatment, etc.).

After a 20-year break R&D work on melamine chemistry and technology was resumed in 2008. In 2011, a variant of modern "alkaline" high-pressure melamine technology was developed, tentatively named «Melamine-NIIK-2011», which is significantly superior to the technology implemented in Kirovakan.

In 2012, on the basis of this technology, after radical changes in the synthesis and separation units of melamine, the technology "Melamine-NIIK-2012" . was developed. The developed technology of high-pressure melamine "Melamine-NIIK-2012" is a modern version of the "alkaline" technology of Montedison. Licensors of melamine technologies are currently Eurotechnica ("ammonia" technology), Borealis Agrolinz Melamine and NIIK ("alkaline" technology) - high pressure technology and, DSM - low pressure (catalytic) technology.

JSC NIIK has experience in designing industrial plants for melamine production from urea plant using high-pressure process. This proposal is based on its own package of know-how accumulated during research and design activities, scientific support and technology improvement of existing industrial plants.

NIIK implemented projects for production of various triazine derivatives including cyanuric acid, organic and inorganic cyanurates and isocyanurates, etc. A semi commercial unit for melem production using dicyandiamide and\or melamine was designed and constructed in Kirovakan.