10/11/2023

10/11/2023

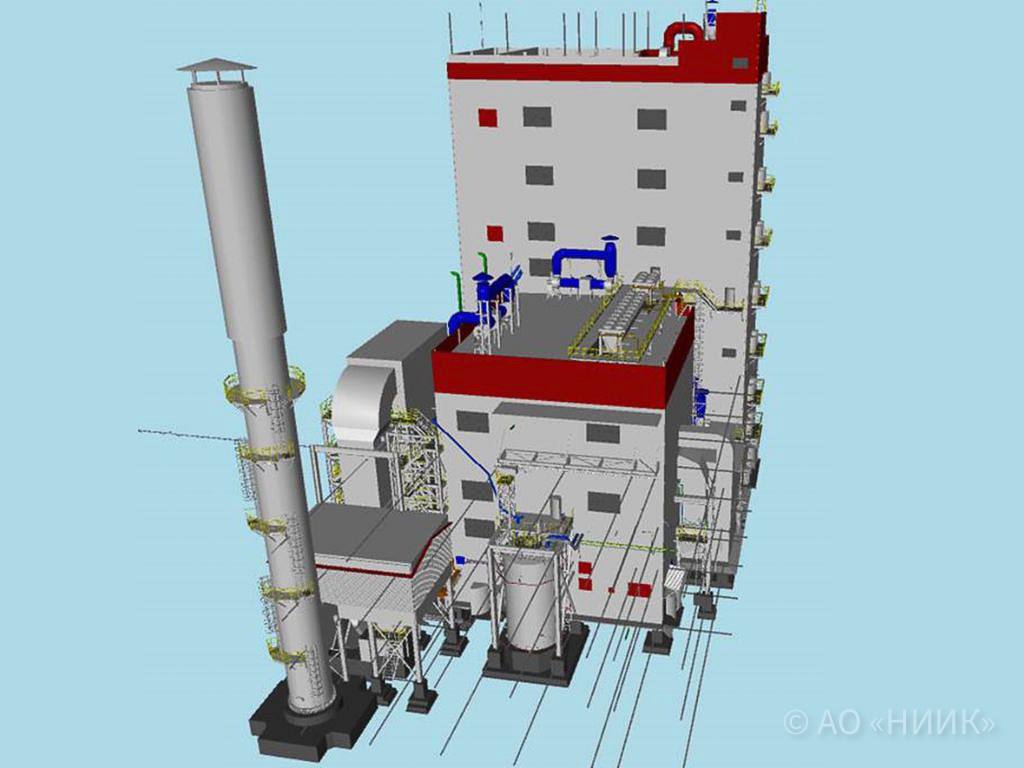

JSC NIIK is developing BE package for Granulation Unit based on proprietary technology

Russian urea producers have already shown high demand for the latest NIIK developmentNew developments in NIIK's fluidized bed granulation unit include high production capacity (up to 3000 TPD), advanced air distribution unit in the nozzle area, coarse average granule size (more than 3 mm), high strength of the product (at least 2.5 kgf/granule) and resistance to mechanical impacts during transportation and storage.

Environmental care is a priority for our company, so the new technology implements the best solutions aimed at reducing emissions. Low energy consumption for the production process and air purification is guaranteed, and the waste air is purified from ammonia and urea dust to 20 mg/Nm3 and 20 mg/Nm3 respectively (using acid recovery).

Thanks to the improved solutions of NIIK the modes of product movement in the nozzle area have been changed, the product removal from the spraying area has been intensified and the influence of change of air flow rate supplied to the nozzles on the quality of the obtained product has been reduced.

The most important feature of the designed unit is the presence in its design of a large range of equipment manufactured at Russian factories, as well as the NIIK's proprietary scientific developments.

Galina Dolganova, Project Manager: "NIIK has received several requests from Russian fertilizer companies to develop a project for Granulation Unit construction. This will allow our company to become the only one in the industry ready to offer technology that will be an alternative to foreign licensors, particularly Chinese ones,”