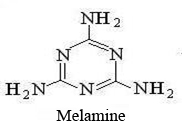

Melamine — 1, 3, 5-triazine-2, 4, 6-triamine.

Chemically pure melamine has the form of colorless and odorless crystals partially soluble in water (approximately 4g/l solubility) and the majority of organic solvents.

Chemically pure melamine has the form of colorless and odorless crystals partially soluble in water (approximately 4g/l solubility) and the majority of organic solvents.

Melamine falls into the chemical class of cyclic cyanamides and exhibits a range of properties resulting from energetic stability of triazine nucleus (heat-, light- and chemical resistance and ability to create polyfunctional reactive chemical combinations) which explains strong demand for melamine in the Russian market.

Melamine is the most important semi-finished product in plastics industry. Melamine-formaldehyde resins production is the largest consumer of melamine widely used in manufacturing of various household and industrial purposes products.

Solidified melamine resins, the so-called cross-linked polymers, show high strength, heat-, water-, wear- and light resistance which compares favorably with urea formaldehyde resins. Products produced of such polymers have the following advantages: significantly lower toxicity level, higher strength and heat resistance, resistance to ignition, better appearance and ability to be colored in various colors.

Solidified melamine resins, the so-called cross-linked polymers, show high strength, heat-, water-, wear- and light resistance which compares favorably with urea formaldehyde resins. Products produced of such polymers have the following advantages: significantly lower toxicity level, higher strength and heat resistance, resistance to ignition, better appearance and ability to be colored in various colors.

Two types of melamine production units had been in operation until the 70s of the 20th century: dicyanodiamide based and urea based.

Starting from the 70s two urea based melamine processes have been used: low pressure (LP) process (1-7 atm.) with application of a catalyst and high pressure (HP) process (80-100 atm.) under temperature 380-400°С.

At the beginning of the 60s NIIK (earlier referred to as GIAP) specialists were the first ones in the world to develop a continuous process of melamine production from dicyanodiamide.

From the end of the 60s NIIK specialists have been working on its proprietary urea based melamine process. At the present time the company possesses its state-of-the-art high pressure melamine process.

In addition to that, NIIK renders the full range of services in the field of melamine quality evaluation, all impurities identification in melamine supplied to the consumers and produced with application of various processes of certain companies. A similar cooperation has been established with Akron starting from the year 2010. In 2011-2013 a large scope of works on imported melamine quality evaluation was fulfilled by NIIK jointly with Himtek, St.-Petersburg.